GROUND IMPROVEMENT STARTS HERE

As the only standalone ground improvement contractor in Australia and New Zealand, we are well-placed to be your trusted partner in providing foundation systems.

We reduce the geotechnical risk for our clients by combining creative design and implementing innovative solutions. We target economical and sustainable solutions to improve the stability of compressible soft soil foundations and reduce the requirement for deep foundations.

Our experience in ground improvement, specialist foundations, ground reinforcement, environmental remediation, and drilling has facilitated the delivery of cost-effective solutions for the construction of a wide range of projects.

Foundation solutions based on

ground improvement and

reinforcement technologies

We improve unstable or compressible soft soil into solid foundations to ensure the success of your project. Our expertise in ground improvement, specialist foundations, all methods of grouting and environmental remediation has facilitated the delivery of cost-effective solutions for the construction of a wide range of projects.

Our applications

Buildings | Infrastructure | Process & Energy | Environmental RemediationOur techniques

All of our ground improvement techniquesSectors & Techniques

Menard delivers the full range of ground improvement techniques to provide effective, innovative and economical solutions for its clients. Our teams design, build and refurbish all types of ports, airports, highways, railways, buildings, process and energy infrastructure.

Infrastructure

At Menard, our wide range of techniques enables us to come up with solutions that will help you build your infrastructure on solid ground. CONTACT US Ports and Airports Given the large surface areas (several hectares in many cases) which are generally required, [...]

Process & Energy

Menard provides ground improvement solutions for all types of process and energy projects, from small to large, all around the world.

Mine Backfilling

Mine Backfilling is a technique where filler material is mixed with cementitious material to fill and stabilise underground cavities. It can be used in various mining operations, such as mine tailings stabilisation. Presentation and key elements What is it? Mine backfilling is a technique [...]

Micropiling

Drilled micropiles are piles with diameters of up to 300mm. They are constructed by installing reinforcement bars or casings and grouting them. It's a cost-effective technique. Presentation and key elements What is it? Drilled micropiles are piles with diameters of up to 300 mm. They [...]

Anchoring

Ground anchoring is a technique that connects structures with the soil. It's commonly used to provide stability and reduce the deformation of retention walls. Presentation and key elements What is it? Ground anchoring is a technique that connects structures to the soil or underlying rock [...]

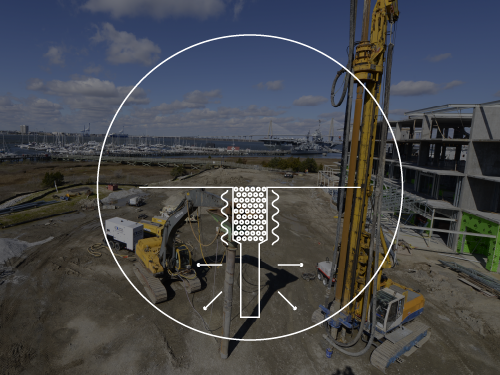

Controlled Modulus Columns (CMC)

Menard developed Controlled Modulus Columns in the 1990s to overcome problems of lateral confinement in highly compressible and organic soils. They are now used in all types of soil (cohesive or granular) up to depths of 30 metres or more.

Stone columns

Stone columns is a ground improvement technique that reinforces the soil with a network of stone compacted columns.

Bi-Modulus Columns

Bi-modulus columns is a ground improvement technique that reinforces the soil by a combination of CMC and stone columns.

Soil Mixing

Soil Mixing is a ground improvement technique that reinforces the soil by mixing in situ a network of grout and soil columns.

Slurry wall

Slurry Wall is a ground improvement technique that uses non-structural underground barriers to build cut-off walls to prevent the flow of water.

Jet grouting

Jet grouting is a ground reinforcement technique. One or several jets of fluid with high kinetic energy are used to break apart and mix the ground with a liquid cement slurry so as to form a column of “soil concrete”.

Dynamic compaction

Dynamic compaction is a ground improvement technique that densifies the soil by repeatly pounding it with a high energy pounder.

Dynamic Replacement

Dynamic replacement is a ground improvement technique that reinforces fine grained soils with a network of dynamically pounded pillars.

Compaction Grouting

Compaction grouting is a ground improvement technique that densifies the soil by grouting under pressure a network of inclusions.

Rapid Impact Compaction

Rapid Impact Compaction is a ground improvement technique that densifies the soil by pounding it at high frequency with a medium sized pounder.

High Energy Impact Compaction

The technique of High Energy Impact Compaction (or Impact Roller Compaction) involves application of high energy impulsed at the ground surface utilizing rollers.

Vibrocompaction

Vibrocompaction is a ground improvement technique that densifies the soil by shaking it with a vibro probe.

Vertical drains

Vertical drains, also known as prefabricated vertical drains or wick drains, are made up of a plastic core surrounded by a geotextile that acts as a filter to prevent clogging.

Menard Vacuum™

Menard Vacuum™ is used to accelerate consolidation of cohesive, highly compressible soils. The process consists in creating a negative pressure under an airtight membrane laid over the soil, which generates atmospheric pressure on the soil, equivalent to the pressure exerted by a 4 metre embankment.

YOUR LOCAL CONTACT

Menard is present in all regions of Oceania, with local offices in all of these areas. Our goal is to serve the local market in each region with our extensive technical knowledge of our techniques and the local geological environments. This regional presence is backed by Menard’s global and technical leadership.

Your local contact

Menard is organised in 7 regions worldwide, our target being to serve the local market in each of those regions through our deep local presence. That local presence is backed by Menard global expertise addressing major projects in those regions together with projects outside of our permanent bases.