Presentation and key elements

What is it?

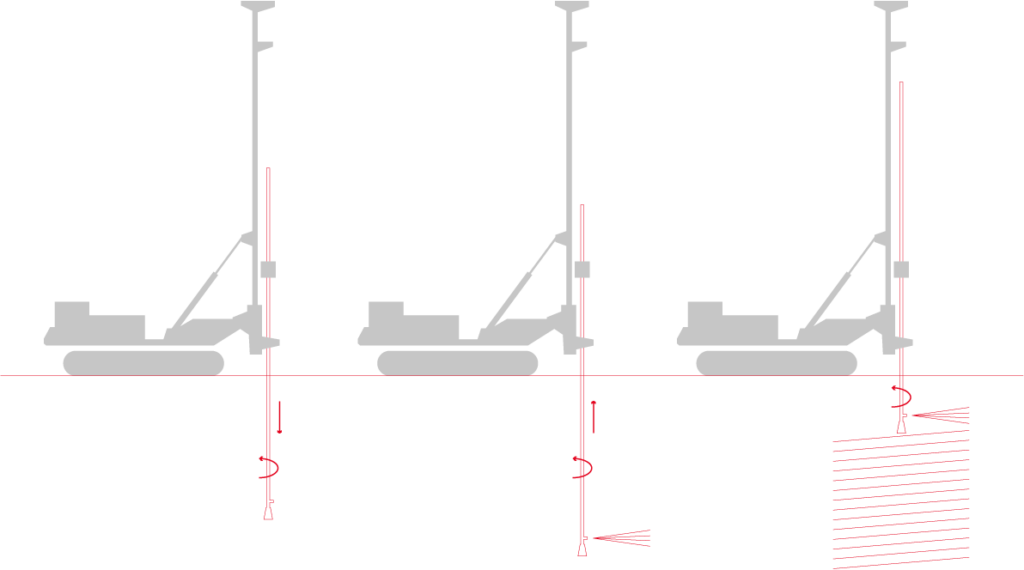

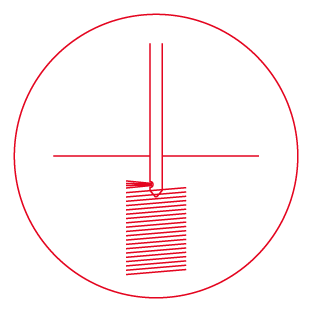

Jet grouting uses fluid jetting with a very high kinetic energy to erode the soil structure and mixes the in-situ soil particles with grout. It creates a homogeneous mass of high strength reinforced soil-cement material.

When and why use it?

Jet grouting is used to control and reduce settlement under structures, increase bearing capacity, create an impervious cut- off wall or reduced permeability base for excavation, install retaining walls, underpin existing structures, and reinforce soils for buried utilities or structures. Depending on the overall design and soil conditions, several methods of treatment have been developed (single or double curtain walls, secant columns walls, plugs, isolated columns, etc.) making jet grouting a flexible technique.

💡 Menard’s tip

Jet grouting can be applied in areas that are difficult to access using inclined columns, directional drilling and masts of different sizes to fit within tight spaces.