Presentation and key elements

What is it?

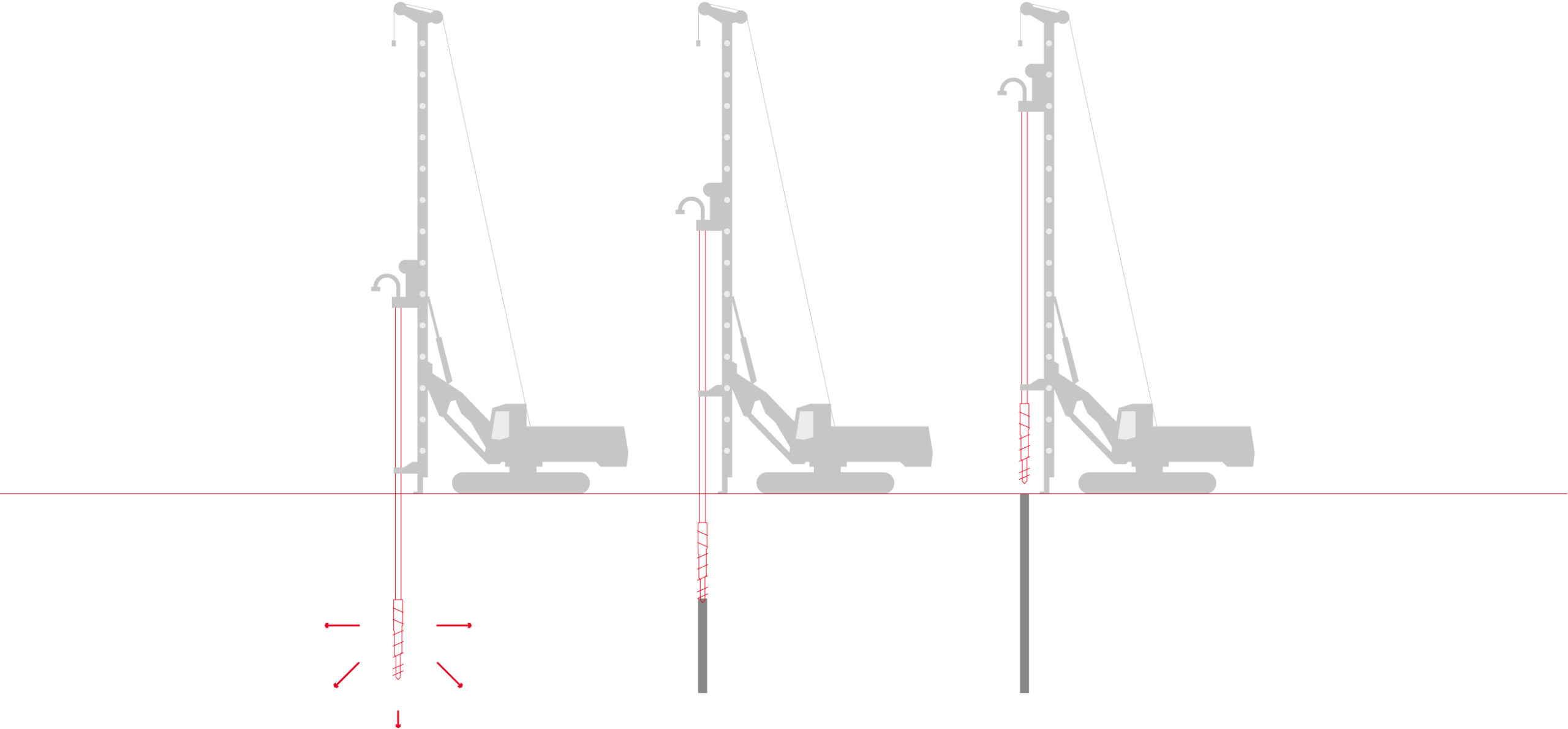

Controlled Modulus Column (CMC) is a rigid inclusion ground improvement method that reinforces the soil with a network of grouted columns. The columns reduce the overall compressibility of the soil.

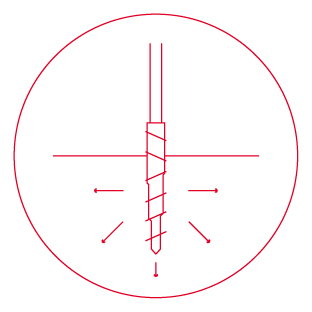

Rigid inclusions are installed using a simple and efficient process with or without soil displacement during drilling. Grout or concrete is injected at low pressure through the hollow stem of the drilling tool. CMC diameters are generally between 280 mm to 450 mm.

When and why use it?

The objective of this solution is to provide an equivalent improved soil mass stiffness to globally reduce total and differential settlements by distributing loads between the ground and the CMCs.

CMCs can be used in all types of loose or soft grounds, including soils with significant organic content and fill material. The technique can uniformly support slab-on- grade, shallow footings, spread footings, strip foundations and retaining walls. The use of a rigid inclusion ground improvement enables us to reduce the cost of the structure (decrease of concrete thickness and steel reinforcement).

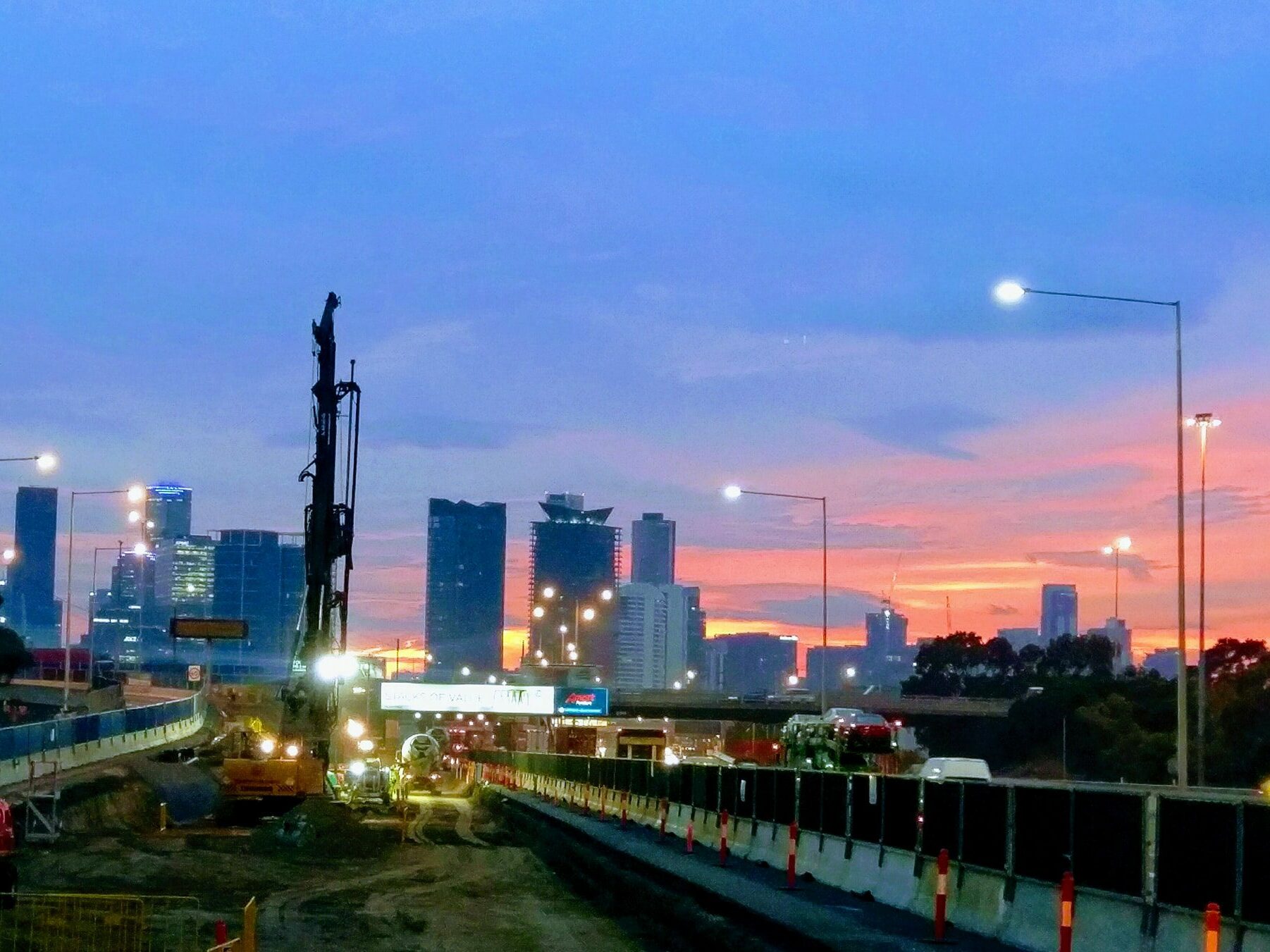

The entire process is vibration-free and generates a very limited amount of surface spoil, which decreases spoil removal costs, limits risk of contamination and makes for a clean working environment.

They are an economical alternative to traditional deep foundation solutions and in most cases can prove to be beneficial for the global design of the superstructure.

💡 Menard’s tip

Our CMCs can provide significant savings on both cost and time over more traditional techniques.