Presentation and key elements

What is it?

Vertical drains often called wick drains or prefabricated vertical drains, are made up of a plastic core encased by a geotextile that acts as a filter that allows water to enter the drain without soil clogging it.

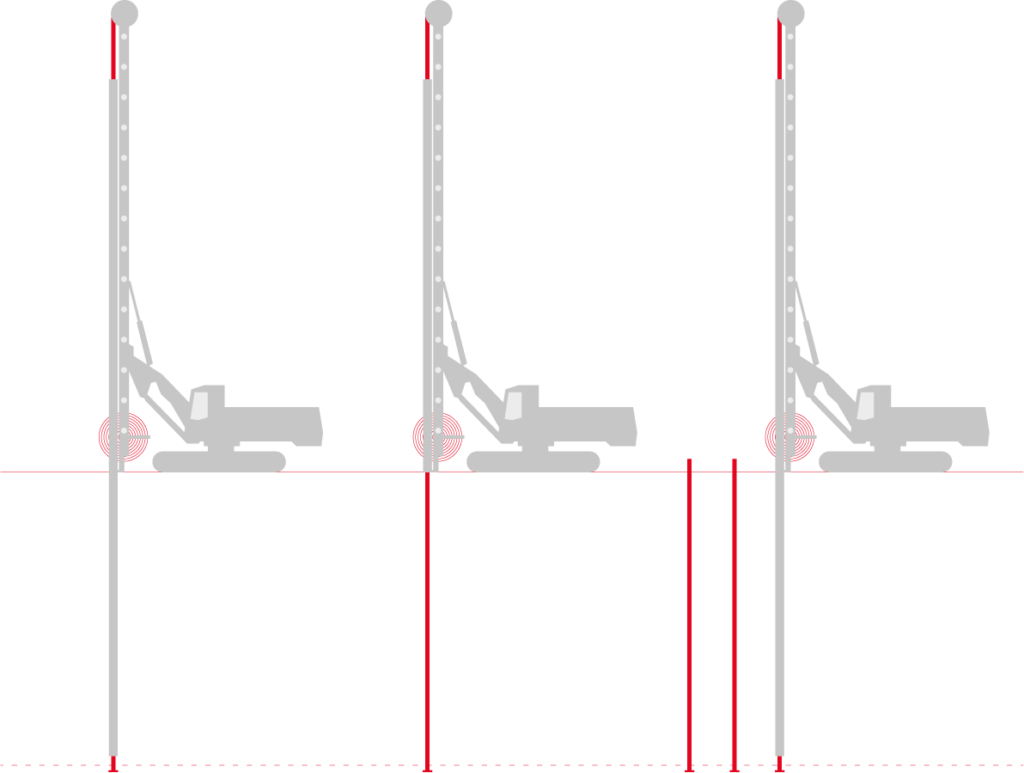

The vertical drains create paths that accelerate water drainage and consolidation of saturated cohesive compressible soils. The drains are installed in a grid that is designed to satisfy the settlement requirements.

There are various types of vertical drains (round and flat) and various sizes to suit project requirements.

When and why use it?

Fine cohesive soils have low permeability and it takes relatively long periods for them to consolidate under loads. Installation of vertical drains greatly shortens the water drainage path and significantly reduces the consolidation time.

The machines used can conventionally install drains up to depths of about 50 meters.

💡 Menard’s tip

The combination of vertical drains with preloading or a surcharge program accelerates the consolidation period.