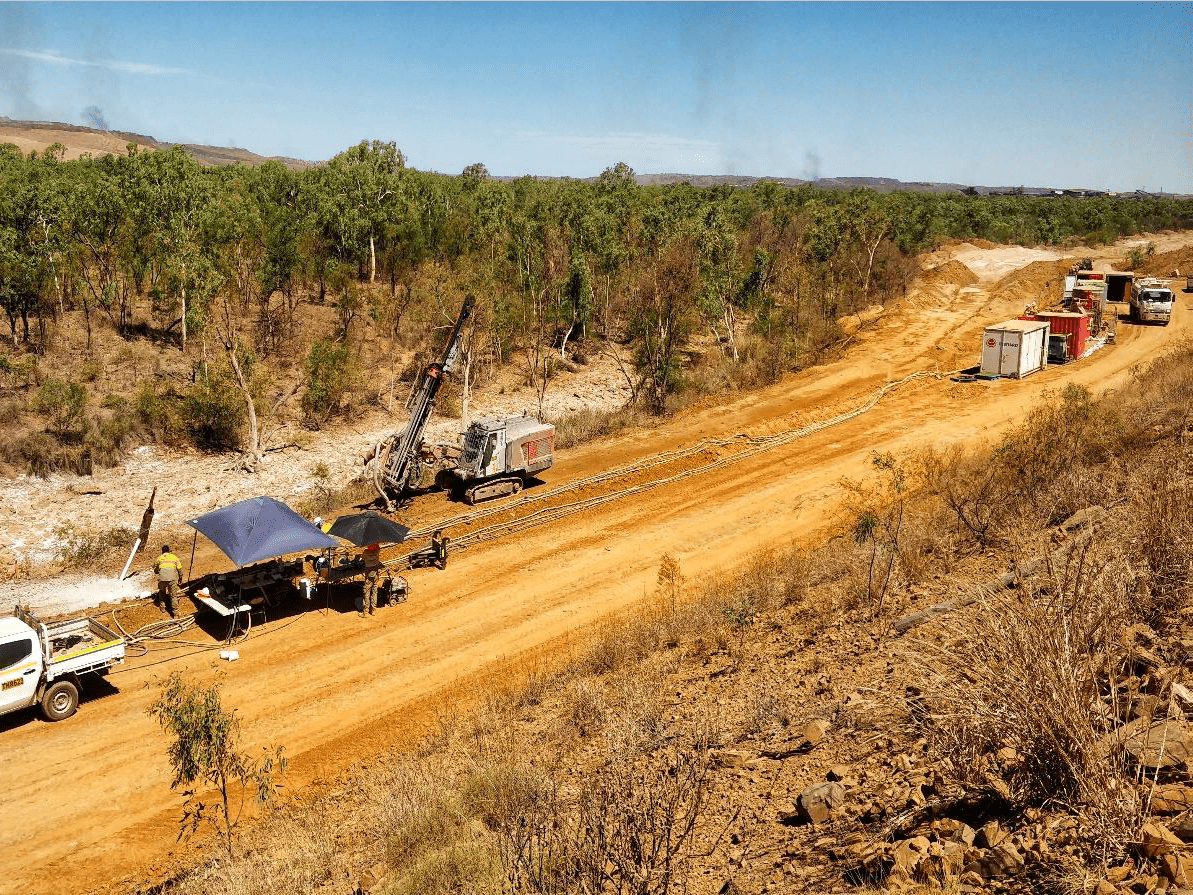

Maroon & Moogerah Dam Upgrade

Maroon Dam, was constructed between 1969 and 1974, located on Burnett Creek Southeast Queensland. The

dam embankment comprises an earth and rock-fill section with a height of 47m and a crest length of 457m.

Stage 1 Upgrade program was designed to limit seepage and ground pressure during flood events. Works

comprised the extension of the existing grout curtain and pressure relief wells both of the abutments.

Geological site conditions were highly complex with evidence of faulting, igneous intrusions, stress relief and

tectonic shearing. The material along the potential failure planes comprises clay within the rock formation,

landslide clay and shear materials.

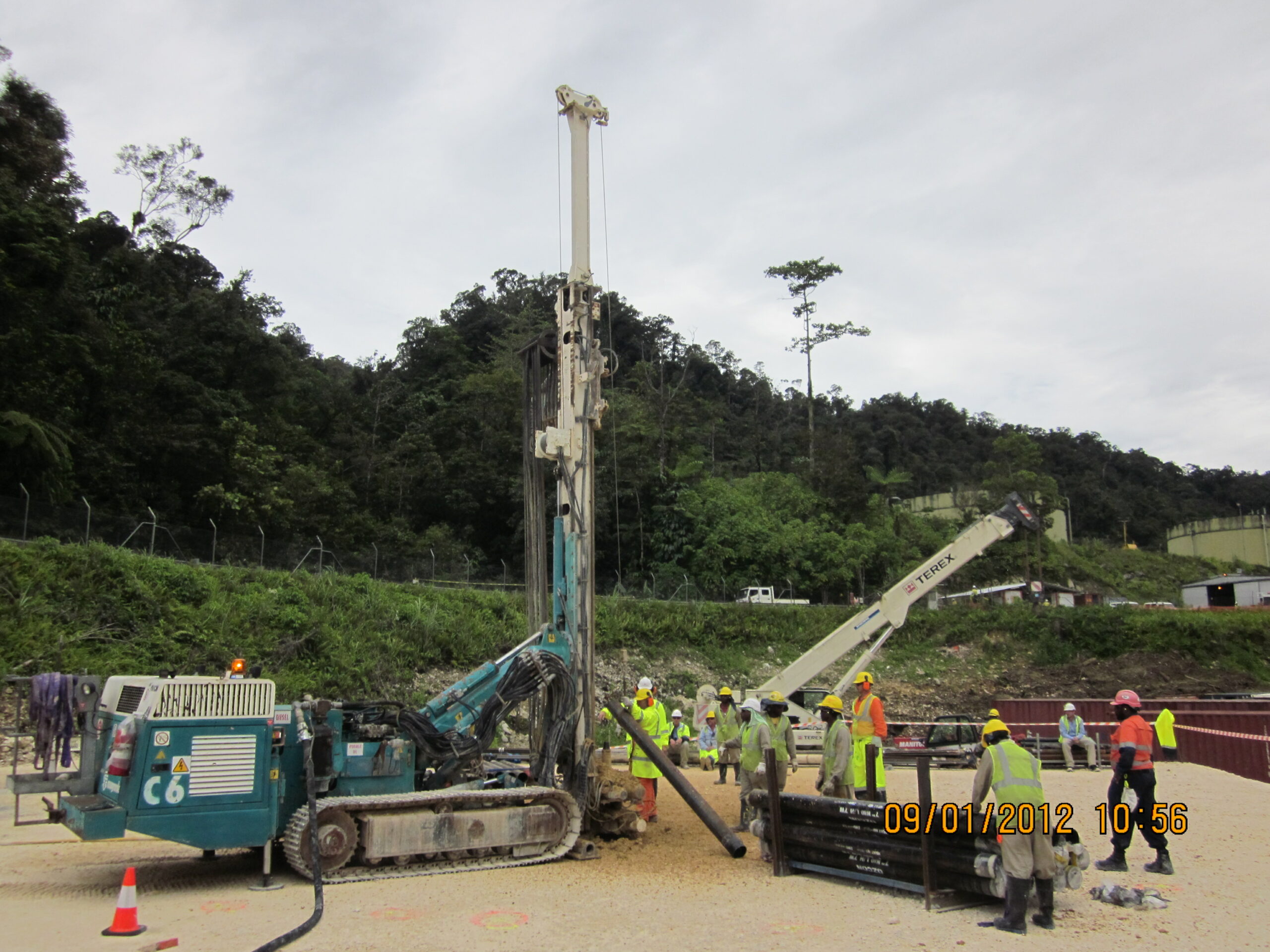

To reduce the permeability of the foundation below the dam Menard Oceania constructed two continuous single-

line grout curtains, together with layers of consolidation holes on both left and right abutments.

To undertake these complex works Menard Oceania developed a real-time control software, SPHINX99 and

SPICE_04 that operates special grouting equipment, ARCSINNUS. This real time system, reduces the reliance

on manual observation and allows continual adjustment to the process by the grouting engineer. This setup

allows Menard to produce a high level of efficiency and quality control.

At project commencement, a 12m long trial panel on Left Hand Abutment, including three primary holes at 6.0m

spacing and associated secondary and higher order holes at evenly split spacing, shall be carried out to confirm

the Grout Intensity Number (GIN parameters). Following this trial stage, an increase to the grouting scope by

more than three times was required. Consequently, grout curtain and consolidation depths were extent to 52m

and 24m, respectively.

To manage the increased scope to an acceptable program Menard worked together with clients design team to

propose alternative design solutions that included, mix design, pressure, grouting and water test sequences.