WestConnex 3B Rozelle Interchange Project

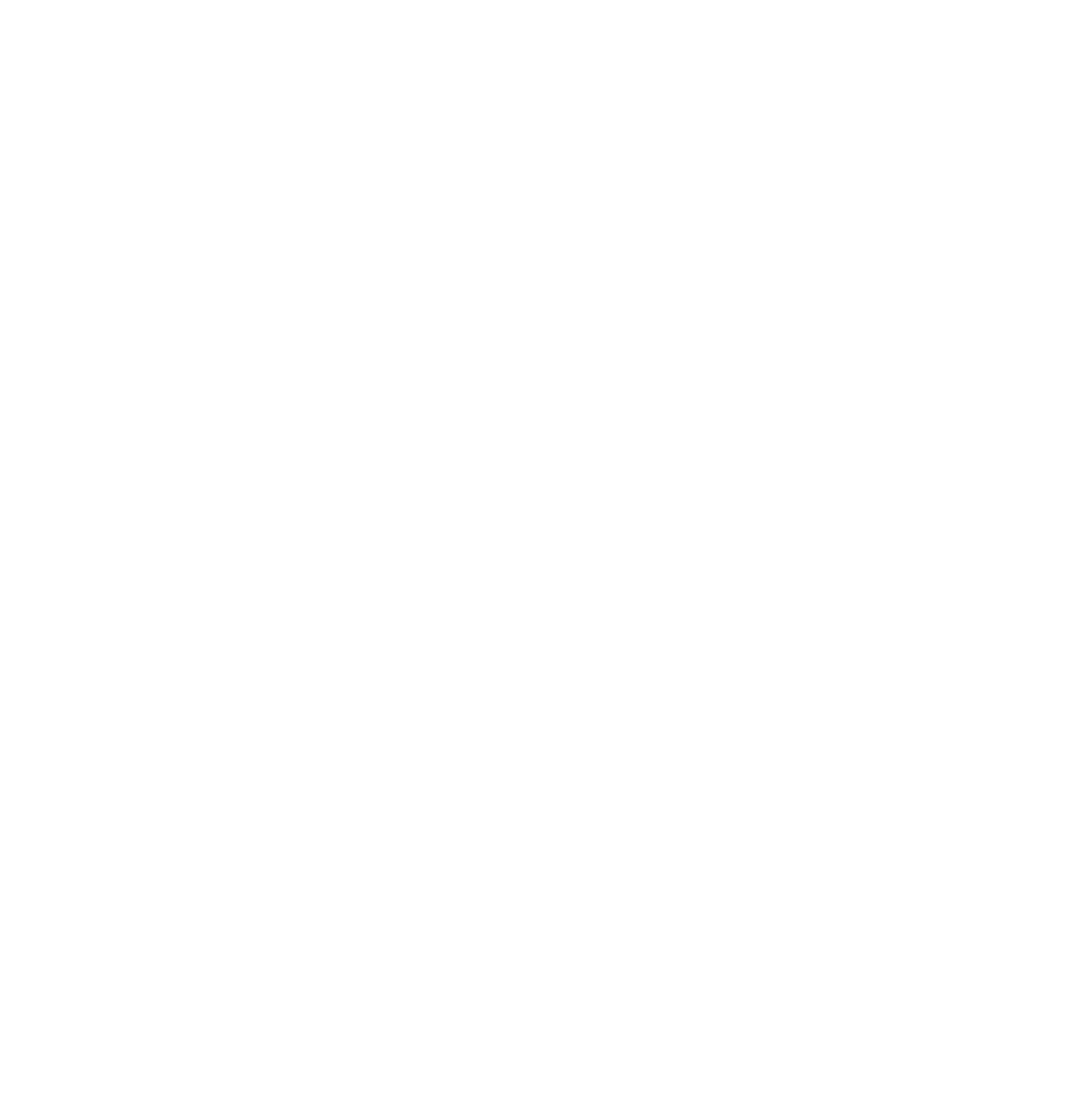

The John Holland CPB Contractors Joint Venture has been engaged to design and construct the Rozelle

Interchange as part of WestConnex 3B. The project will create a new underground motorway interchange which

provides connectivity to the M4-M5 Link Tunnels, the new M8 tunnels and the City West Link, and underground

bypass of Victoria Road between Iron Cove Bridge and Anzac Bridge. The Rozelle Interchange also provides a

connection to the future Western Harbour Tunnel.

The project site consists of 3 separate tunneling sites and 2 Cut and Covers operating from the same footprint.

This enables 22 road headers to build the underground interchange, with the Cut and Covers providing a link to

the already traffic dense surface roadway.

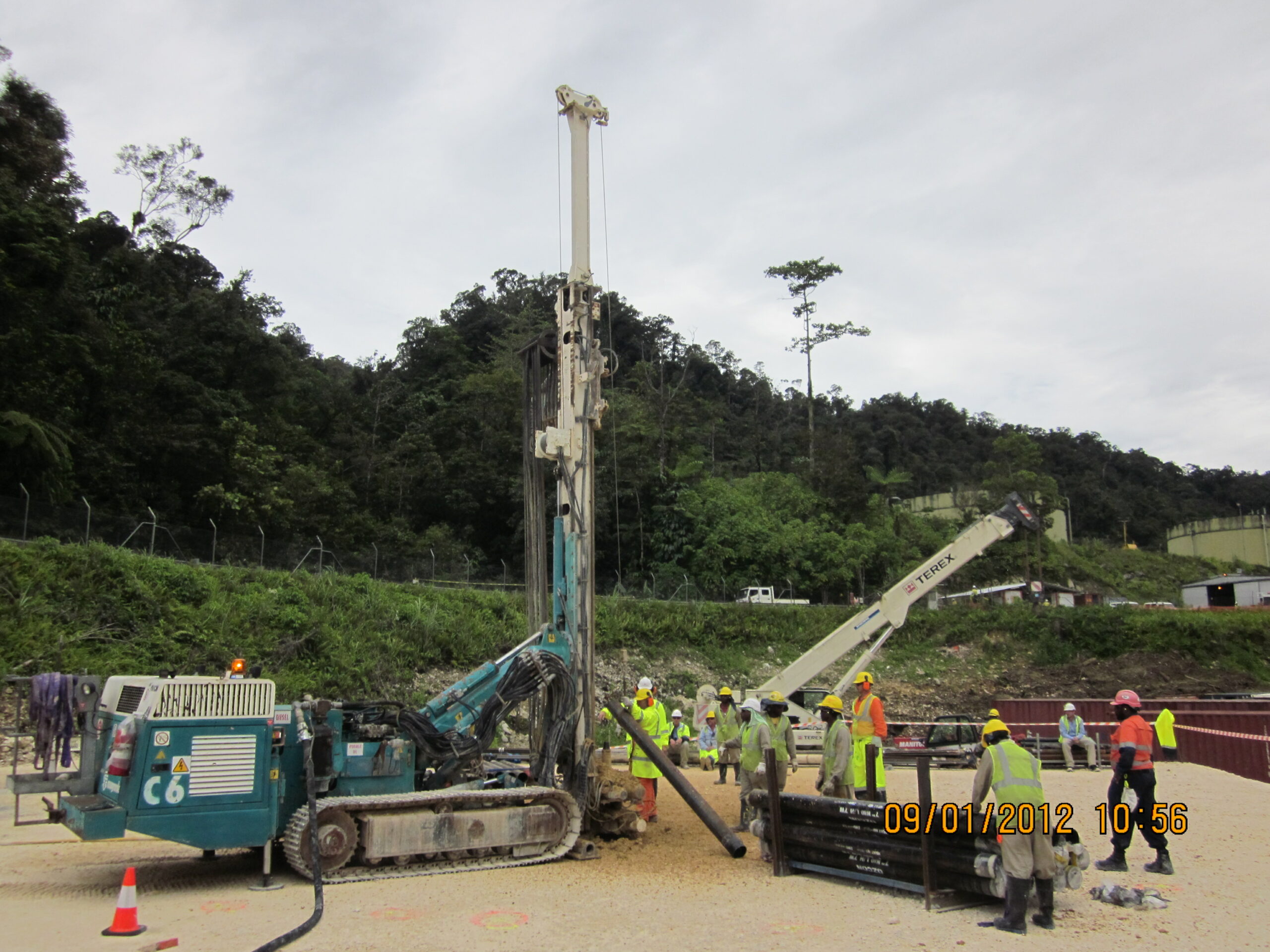

As part of the project, Menard Oceania has been appointed to complete the permanent grout curtain works in

several locations on the project. Permanent grout curtains were utilised in order to limit groundwater ingress into

the tunnels, shafts and Cut and Cover structures.

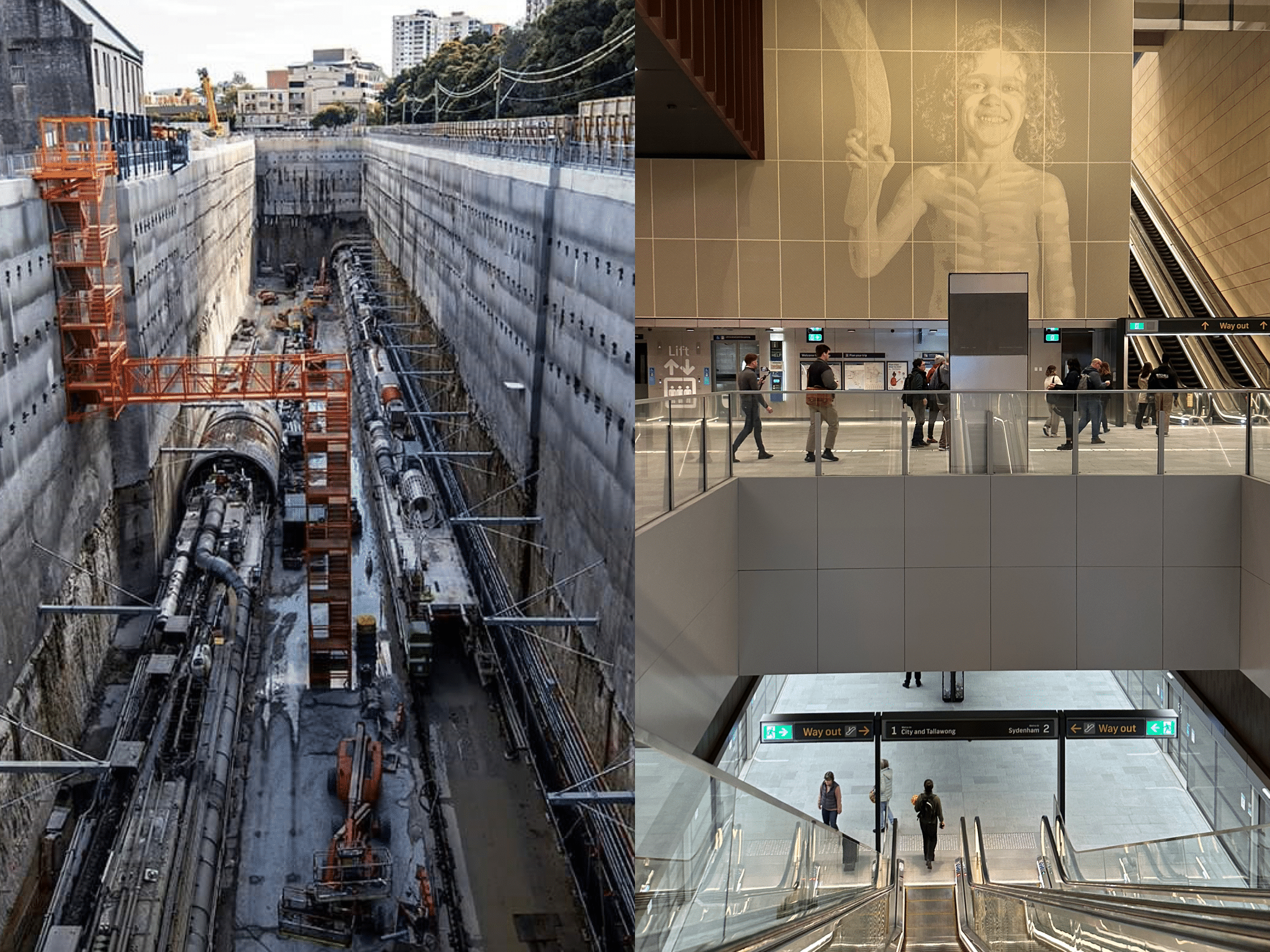

The general ground conditions consisted to sand and clay to depths of 8-18m on top of Hawksbury sandstone.

Sections of the sandstone was highly fractured increasing the permeability of the rock feature. A dyke

intersected the middle of the site causing highly fractured and weathered sections to be charged with water.

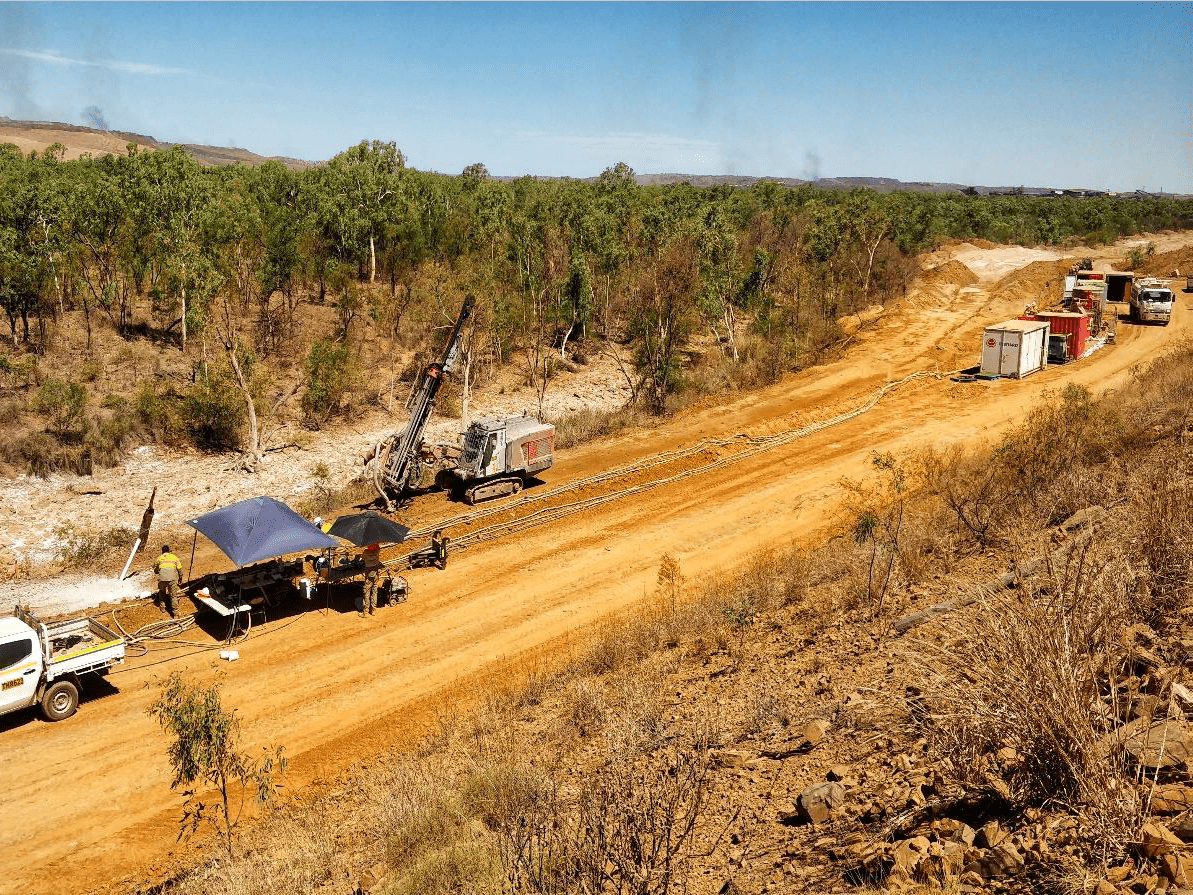

In order to reduce control water inflow in the cut and cover prior to the bulk excavation, a grout curtain along the

perimeter of the cut and cover was required. The curtain extended 10m below the Bulk Excavation level and was

designed to be 6m wide offset behind the pile alignment.

This grout curtain campaign was particularly challenging from a logistical and technical perspective, due to the

interfacing with numerous trades on surface level while navigating around a site parallel to the busiest

intersection in Sydney.

Menard utilised the expertise of the Vinci Group to apply in house grouting software to install the grout curtain

utilising the GIN methodology. GIN grouting, provides a high level of control of the grouting application, through

parameter driven flow rates, injection pressure and GIN numbers. The system as a whole facilitates highly

accurate quality reporting and facilitates confirmation on the success of the grouting campaign.

Over a period of 6 months the Menard grouting team injected 451 200 L of grout into the highly fractured rock,

minimising the amount of water ingress that will be experienced during tunnel excavation, allowing for the project to achieve the highly limited inflow criteria along the tunnel length.