Melbourne Metro Tunnel Project

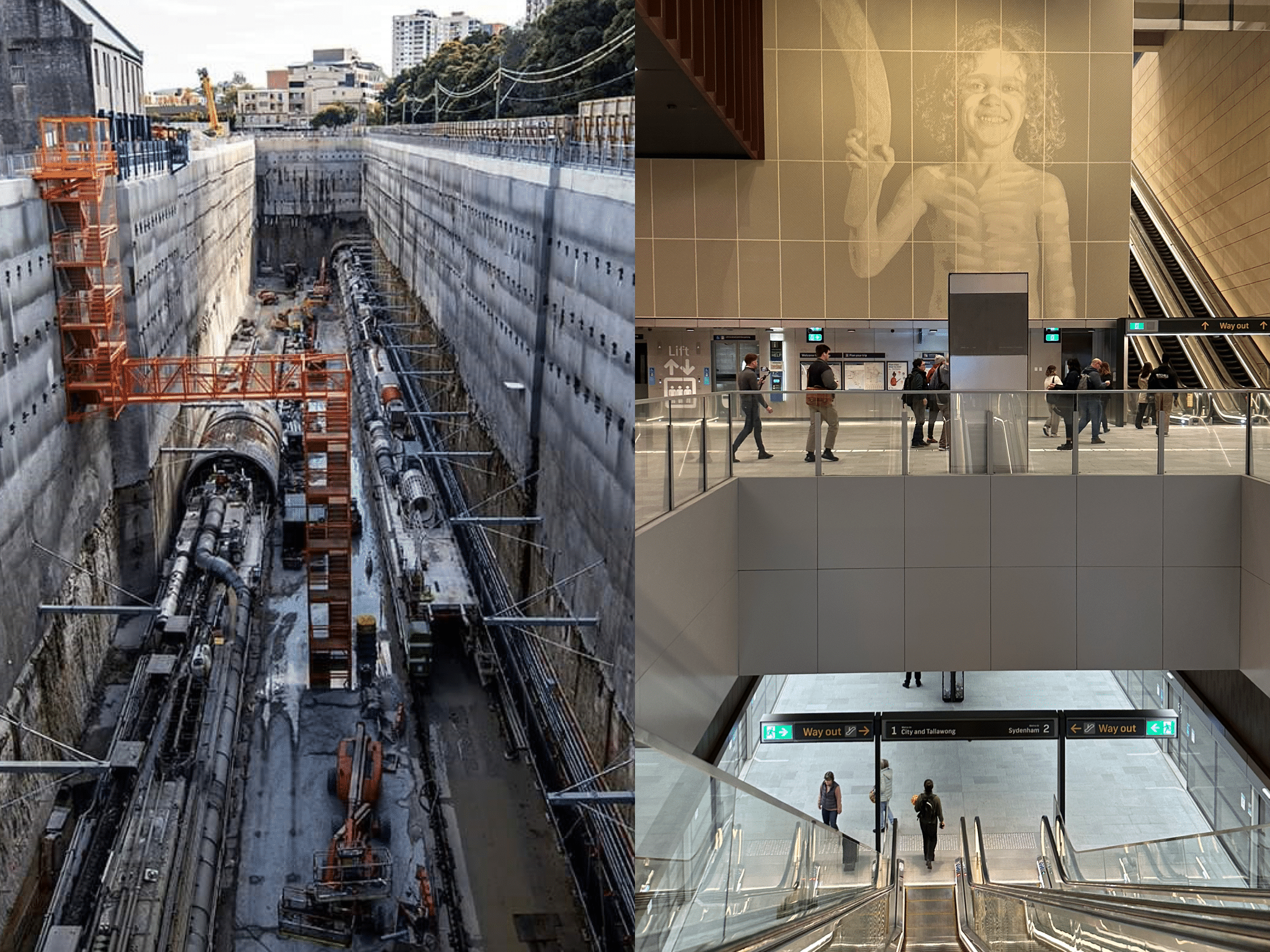

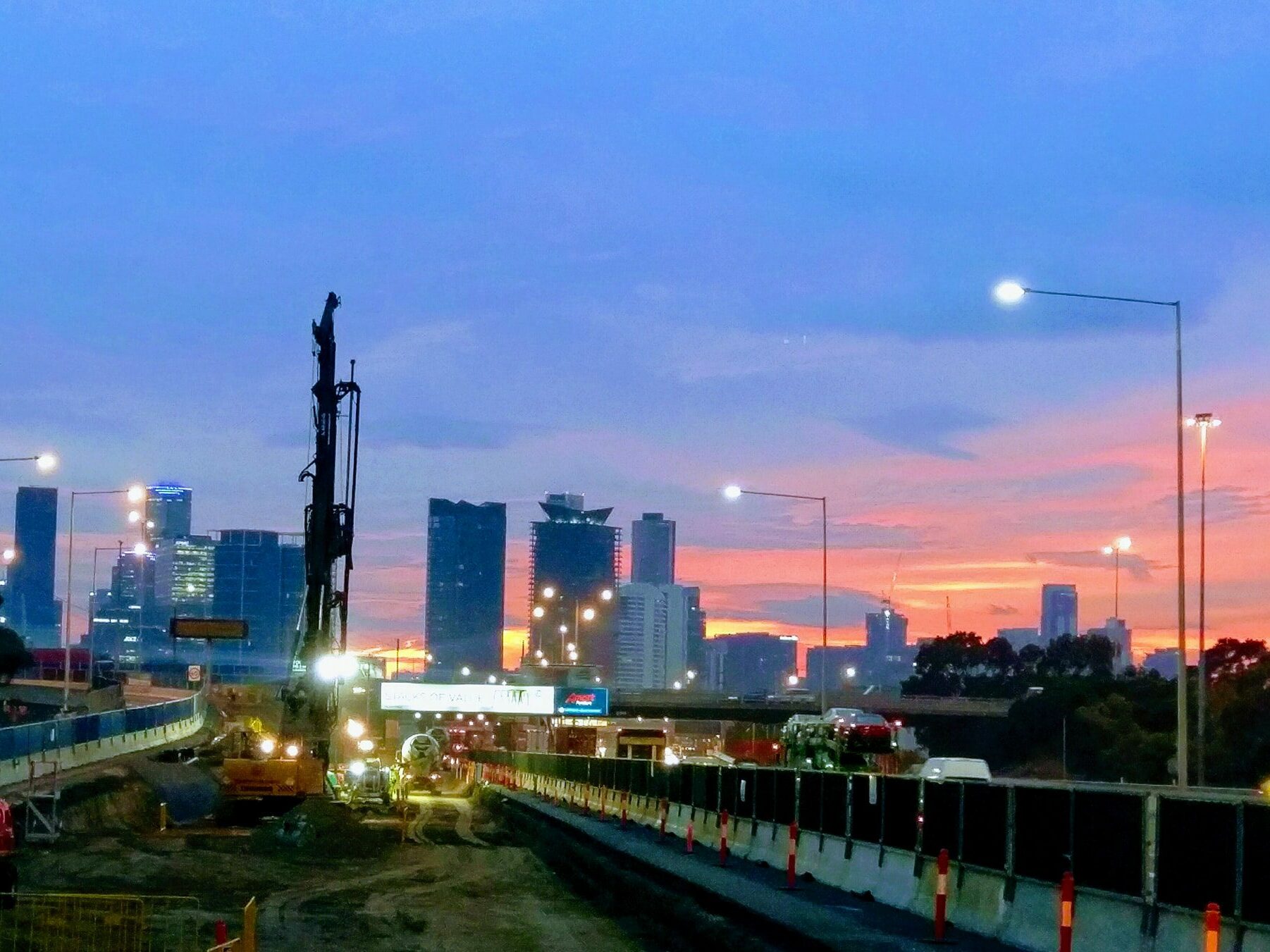

The $11 billion Melbourne Metro project is the largest transport infrastructure project in Victoria to date. The Project comprises of twin 9-kilometre-long by 6.9m internal diameter tunnels providing North-South underground rail connection across Melbourne Central Business District from Western Portal near Kensington Road to Eastern Portal near Chapel Street, South Yarra. New underground railway stations will be constructed at Arden, Parkville, CBD North, CBD South, and Domain. As part of the works, 26 cross passages are to be constructed at approximately 230 metres apart along the tunnel alignment. Cross passages are constructed from below ground within the tunnels after the tunnel boring machines (TBMs) have passed through. These passages are an important safety feature that allows people (including emergency services) to move from one tunnel to the other in the event of an emergency as well as hosting a maintenance facility for drainage. There was a requirement for ground treatment between tunnels, specifically at cross passages where the ground was identified as not being sufficiently competent to safely execute underground activities such as the safe removal of precast concrete segmental tunnel linings at cross passages and excavation of the cross passages. Cross passages CP02, CP03, CP04, CP05, and CP15 are located within soft or mixed ground conditions which required ground treatment to control groundwater ingress and/or provide suitable ground control to allow stability of mined excavation between the tunnel tubes.

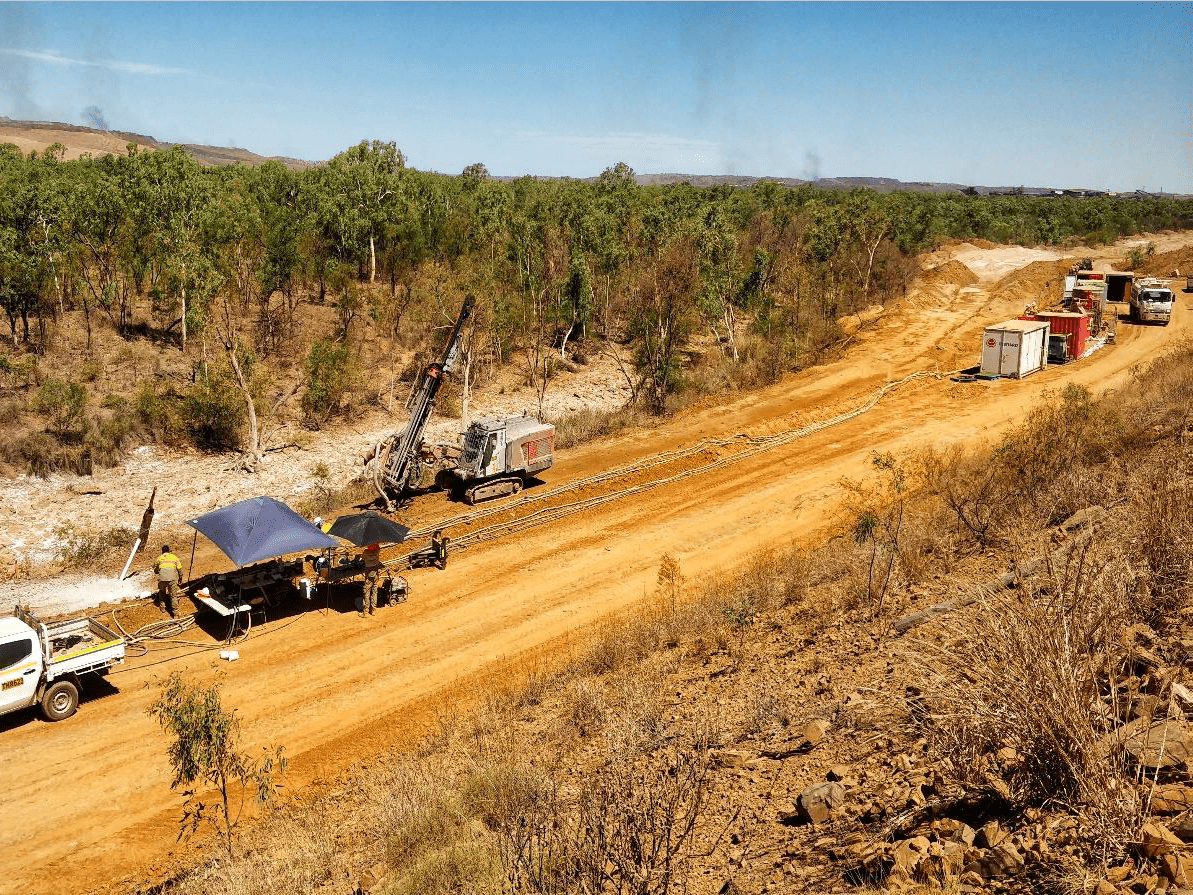

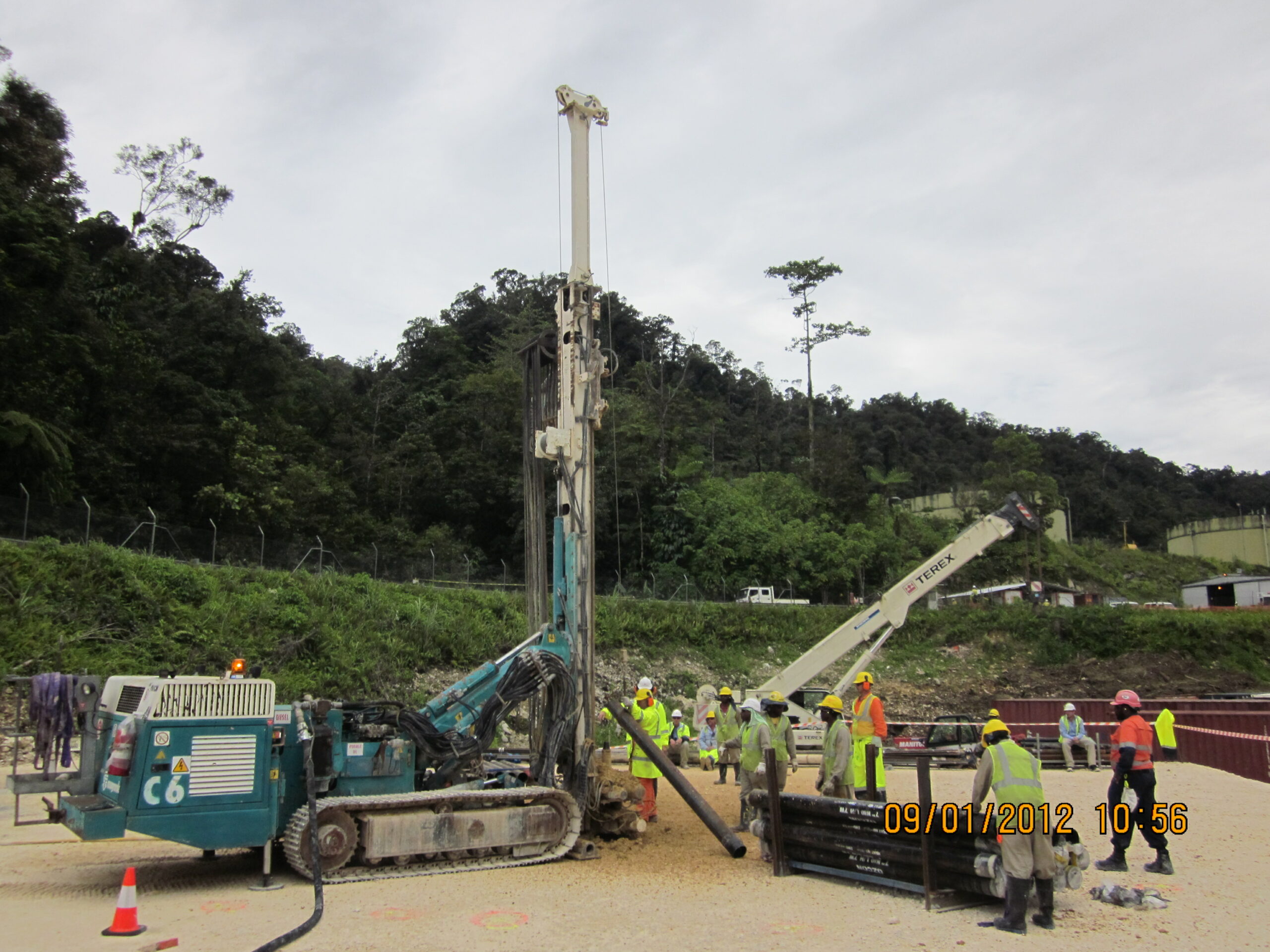

CYP consortium awarded Menard Oceania (MO) as specialist geotechnical sub-contractor, for all the ground treatment works. The proposed ground treatment principally consisted of overlapping jet-grouting columns, forming a homogenous treated block installed from ground surface to depths of approximately 30m. Further, when the cross-passage treatment area intersects rock, rock-grouting treatment was required to reduce the permeability of the rock mass and of the interface between jet and rock to reduce potential water inflow to the future excavation within allowable limits. Double shifts were utilised in 4 of the 5 areas to reduce the program durations. Following the completion of the surface grouting works, Menard was awarded the Probing and Grouting from inside the tunnels for the treated areas. This involved drilling multiple holes from one tunnel towards the second tunnel, approximately 80% of the distance across. Once complete, water tests were undertaken to verify the permeability requirements were achieved, prior to the removal of the tunnel liner and commencement of the mining of the cross passage between the tunnels. The works were safely and successfully carried out over a 2-year duration